Wheat has been cultivated in China for over 4,000 years. As early as the Neolithic Age (about 4,000 years ago), there are records of cooked wheat food in China. By the Chunqiu and Warring States period, fried and steamed wheat foods had appeared. Since then, with the improvement of cooking utensils and stoves, the ingredients, cooking methods and kinds of Chinese wheat foods have become increasingly varied and popular. But how did our ancestors get flour in China? Let’s take a look together!

The Neolithic Age (about 4000 years ago).

As early as 4,000 years ago, our ancestors learned to use tools to remove wheat bran, grind it into powder, and cook it before eating. The tools for obtaining flour at that time were very simple: the wheat was spread on a relatively flat stone, and then a rounded stone was used to grind the wheat into powder.

Neolithic flour-processing stone tools unearthed by archaeologists

Incredibly, although the flour processing tools were very simple, our ancestors could already cook noodles back then! In 2002, the Institute of Archaeology of the Chinese Academy of Social Sciences discovered an upside-down clay bowl at the Lajia site of the Neolithic Qijia culture layer in Qinghai Province. There were noodles preserved at the bottom of the bowl, about 50 cm long and 0.3 cm in diameter. The noodles are uniform in thickness and bright yellow in color, similar to modern ramen in shape. This provided the most direct evidence that our ancestors could cook noodles 4,000 years ago.

Noodles from 4000 years ago

During the Warring States Period (about 2,700 years ago), the mortar and pestle became the main tools for flour processing.

Processing using simple stone tools is time-consuming, labour-intensive, and inefficient. Smart ancestors quickly discovered that force applied to a smaller area can break the grain more finely, so they learned to use mortar and pestle to obtain flour (below is a reference picture). Although it was still processed manually in this period, people had learned to use the principle of leverage to save labour as well as crush the wheat more efficiently.

After the Warring States Period (about 2300 years ago), circular stone mills and water mills appeared.

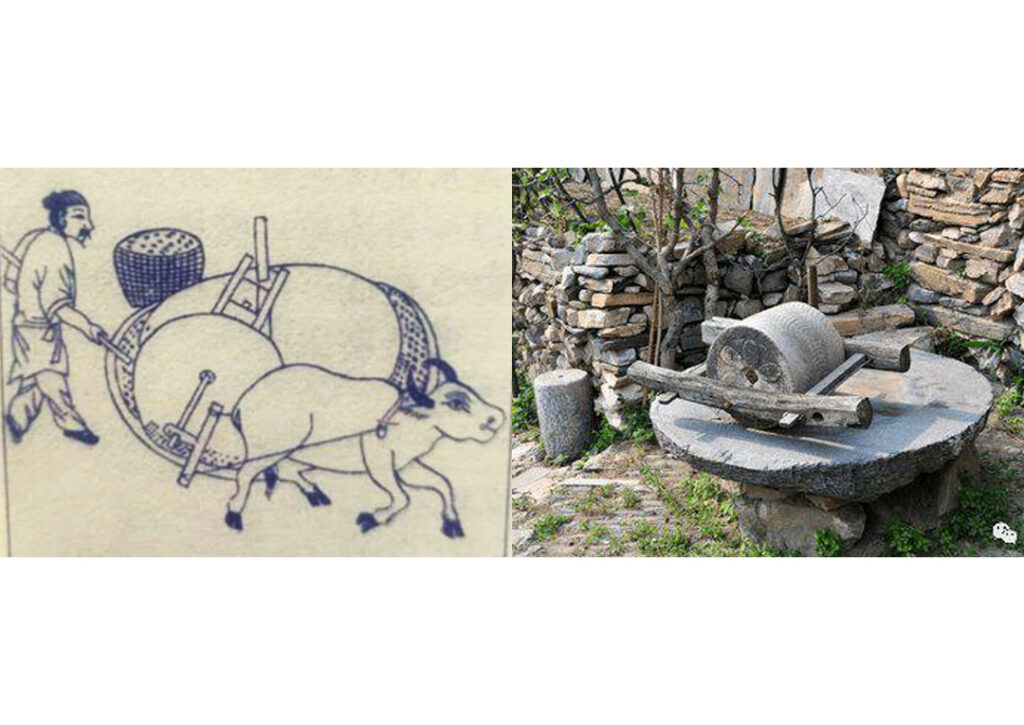

Milling by mortar and pestle was an advance, but it was still a manual process. 2300 years ago, clever ancestors learned to use external energy sources to obtain flour. They invented the stone mill and the water mill! The stone mill is made by stacking two stones with shallow stripes on the surface, with the grain between them. Then a cow or donkey is used to turn the top stone to grind the wheat into flour.

In addition to the use of animal power, our ancestors also learned to use water power to grind wheat. The water mill is an ancient tool for grinding flour, which principally consists of upper and lower millstones, rotating shafts, water wheel and supports. The upper millstone is suspended on the support, the lower millstone is installed on the rotating shaft, and the other end of the rotating shaft is attached to a water wheel. This is driven by the flow of water, thereby driving the rotation of the lower grinding disc to grind grain to obtain flour.

The invention of stone mill and water mill not only saves labor, but also greatly improves production efficiency.

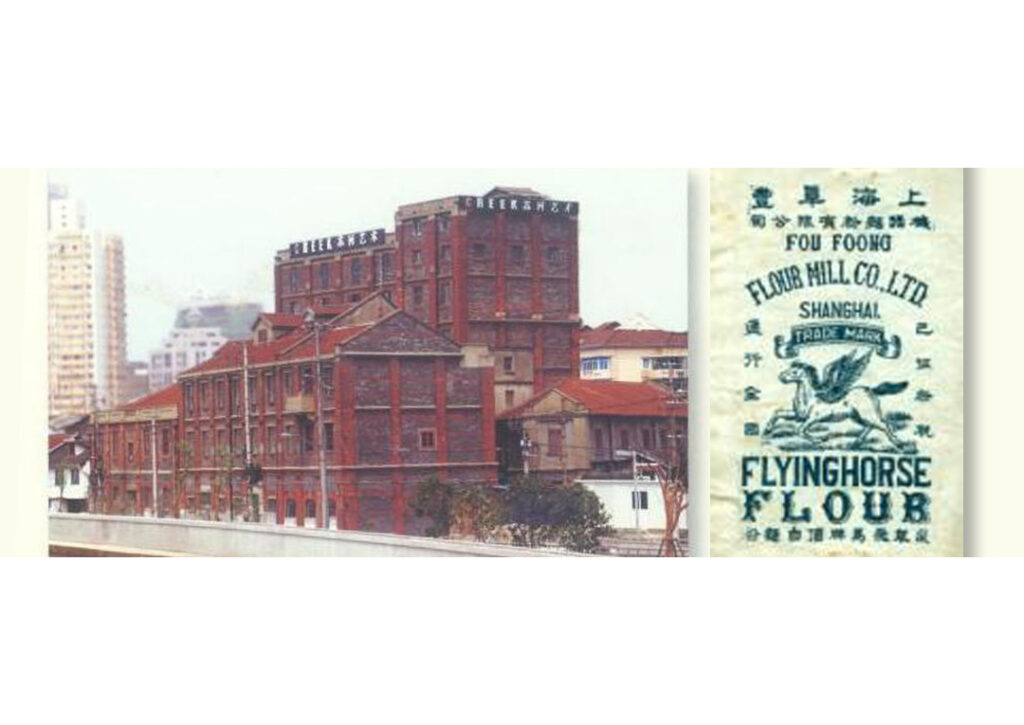

Over the following thousands of years, our ancestors made various improvements to stone and water mills to increase the efficiency of flour production. In modern times the world entered the industrial age, and in the 20th century China also began to have industrialized flour mills.

Fuxin Flour Mill Factory, founded in 1913

Nowadays China is the largest wheat producer in the world, and about 90% of the wheat output is milled into flour, which is then processed into various foods. On a land of 9.6 million square kilometers, from south to north, from east to west, from breakfast to midnight snack, from street corners to high-end Michelin star restaurant, the Chinese people interpret their love for flour in many different cooking styles.

As the leader in the field of flour improvement, the century-old Mühlenchemie company and its parent company Stern Wywiol Group of Germany set up an R&D and manufacturing center in Suzhou, China in 2009, to provide professional and efficient service for flour enterprises in China. Today, at Stern Ingredients (Suzhou) Co., LTD., the R&D experts focus not only on the delicious taste of flour-based foods, but also on the nutrition they provide.

Welcome to China and welcome to Stern Suzhou, to experience the amazing deliciousness of flour in China!

Your Team Stern Ingredients China